Experienced installers thrive on accurate project scoping to avoid underestimation or overestimation, ensuring high-quality work and client satisfaction. They prioritize safety through protective gear, durable finishes, and regular training, minimizing damage and maintaining quality. Regular tool maintenance extends tool life, produces superior installations, and fosters satisfied customers, strengthening their professional reputation.

“Avoid common pitfalls and elevate your installation game with insights from seasoned professionals. This article uncovers critical mistakes that experienced installers expertly sidestep, ensuring project success. From accurately assessing project scope to prioritizing safety and maintaining tools, these strategies are essential for any skilled installer aiming to deliver top-notch results. Discover how to avoid overestimating or underestimating tasks, negate safety hazards, and keep your tools in peak condition for efficient, long-lasting installations.”

- Misjudging Project Scope: Avoiding Overestimating or Underestimating

- Neglecting Safety Protocols: Best Practices for Experienced Installers

- Inadequate Tool Maintenance: Ensuring Efficiency and Longevity

Misjudging Project Scope: Avoiding Overestimating or Underestimating

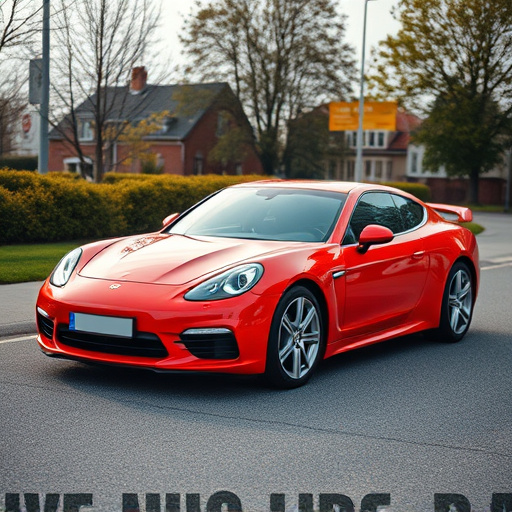

Experienced installers understand that misjudging a project’s scope is a common pitfall many professionals fall into. It’s easy to overestimate or underestimate the time, resources, and skills required for any given task, especially when dealing with vehicle enhancements like custom graphics or protective coatings. Overestimating can lead to delays and additional costs, while underestimating may result in subpar results or missed deadlines.

To avoid these issues, seasoned professionals take their time to thoroughly assess each project. They consider factors such as the size and complexity of the job, materials needed, potential challenges, and required skills. By carefully evaluating all aspects, experienced installers ensure they allocate sufficient resources and set realistic timelines, ultimately delivering high-quality work that meets client expectations.

Neglecting Safety Protocols: Best Practices for Experienced Installers

Experienced installers know that safety is paramount on any job site. Neglecting proper safety protocols can lead to accidents and injuries, which not only jeopardizes the installer’s well-being but also the quality of the work. Best practices include wearing appropriate protective gear such as gloves, eye protection, and high-quality finishes designed for durability and safety. Regular training in safety procedures and adherence to industry standards are crucial for maintaining a secure working environment.

Additionally, experienced installers understand the importance of using protective coatings on surfaces to prevent damage during installation processes. Vehicle wraps, for instance, offer an effective solution for safeguarding painted surfaces while allowing for precise application of graphics or designs. Incorporating these safety measures not only ensures the installer’s comfort and reduces the risk of errors but also contributes to achieving high-quality finishes in every project.

Inadequate Tool Maintenance: Ensuring Efficiency and Longevity

Experienced installers know that maintaining tools is a non-negotiable aspect of their job. Regular cleaning and servicing ensure that equipment remains in optimal condition, maximizing efficiency and longevity. Inadequate tool maintenance can lead to performance issues, increased wear and tear, and even safety hazards. For instance, scratched blades or worn-out components can compromise the quality of installations, such as ceramic window tinting or UV protection films.

By implementing a structured maintenance routine, these professionals safeguard their tools from damage, prolong their lifespan, and maintain consistent performance standards. This meticulous approach translates into higher-quality work, satisfied customers, and continued success in the field, solidifying their reputation as seasoned experts among their peers.

Experienced installers know that success lies in meticulous planning, adherence to safety standards, and proper tool maintenance. By avoiding common pitfalls like misjudging project scope, neglecting safety protocols, and overlooking tool care, these professionals deliver high-quality installations. Their expertise ensures efficiency, longevity, and customer satisfaction, setting a new standard for the industry.